Design and Components:

The Banbury Mixer comprises a robust frame housing essential components such as mixing chambers, rotors, ram, and controls.

Mixing Chambers: Equipped with precisely engineered rotors, the mixer features intermeshing blades that facilitate efficient blending of rubber compounds.

Rotors: Constructed from high-quality materials, the rotors exhibit exceptional durability and performance, ensuring consistent mixing results.

Ram: The hydraulic ram exerts pressure on the material during mixing, enhancing homogenization and dispersion.

Controls: Incorporating advanced control systems, operators can regulate parameters such as temperature, rotor speed, and mixing time, optimizing process control and efficiency.

Operation:

Loading: Raw materials are fed into the mixing chamber either manually or through automated systems.

Mixing: Upon activation, the rotors rotate at controlled speeds, kneading and blending the rubber compounds thoroughly.

Discharge: Once the mixing cycle is complete, the mixer discharges the homogenized rubber batch for further processing or molding.

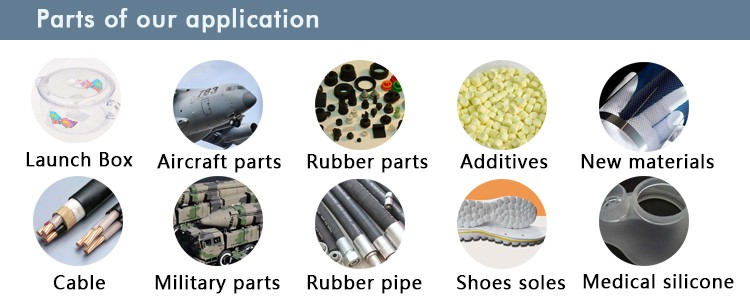

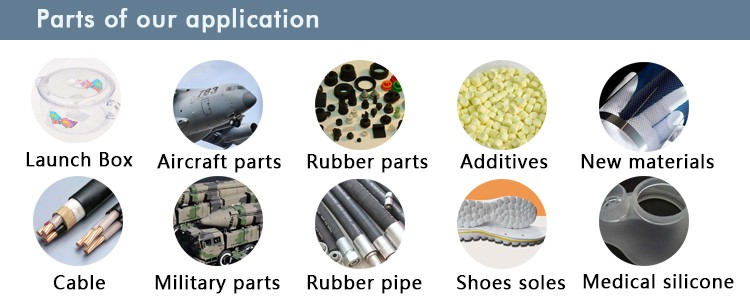

Applications:

Tire Manufacturing: Banbury Mixers play a pivotal role in tire production, ensuring uniformity and quality in rubber compounds.

Automotive Industry: From gaskets to seals, Banbury-mixed rubber finds applications in various automotive components, contributing to durability and performance.

Industrial Products: Rubber compounds processed in Banbury Mixers are integral to manufacturing conveyor belts, hoses, and other industrial products.

Advantages:

Superior Mixing Quality: The Banbury Mixer delivers unparalleled homogeneity and dispersion of rubber compounds, minimizing batch-to-batch variations.

Enhanced Productivity: Streamlined operation and automated controls optimize mixing processes, resulting in higher production throughput.

Versatility: Capable of handling a wide range of rubber formulations and additives, the mixer accommodates diverse industry requirements.

Reliability: Engineered for durability and performance, Banbury Mixers boast robust construction and precise engineering, ensuring long-term operational reliability.

Customization: Tailored configurations and options enable customers to adapt the mixer to specific application needs, enhancing flexibility and efficiency.

The Banbury Rubber Mixer remains an indispensable asset in the rubber processing industry, embodying excellence in design, performance, and sustainability. With its advanced features, versatile applications, and enduring reliability, the Banbury Mixer continues to drive innovation and efficiency in rubber compounding worldwide.

110 Liters Banbury Rubber Mixer

The Banbury Rubber Mixer revolutionizes rubber processing with its intensive mixing action and efficient dispersion of additives. Renowned for its precision, this Banbury Rubber Mixer combines raw rub

TAG: Banbury Rubber Mixer

Description

The Banbury Rubber Mixer stands as a cornerstone in the rubber processing industry, embodying innovation, efficiency, and reliability. With its rich history dating back to the early 20th century, the Banbury Mixer has continually evolved to meet the demanding needs of modern rubber manufacturing. Design and Components:

The Banbury Mixer comprises a robust frame housing essential components such as mixing chambers, rotors, ram, and controls.

Mixing Chambers: Equipped with precisely engineered rotors, the mixer features intermeshing blades that facilitate efficient blending of rubber compounds.

Rotors: Constructed from high-quality materials, the rotors exhibit exceptional durability and performance, ensuring consistent mixing results.

Ram: The hydraulic ram exerts pressure on the material during mixing, enhancing homogenization and dispersion.

Controls: Incorporating advanced control systems, operators can regulate parameters such as temperature, rotor speed, and mixing time, optimizing process control and efficiency.

Operation:

Loading: Raw materials are fed into the mixing chamber either manually or through automated systems.

Mixing: Upon activation, the rotors rotate at controlled speeds, kneading and blending the rubber compounds thoroughly.

Discharge: Once the mixing cycle is complete, the mixer discharges the homogenized rubber batch for further processing or molding.

Applications:

Tire Manufacturing: Banbury Mixers play a pivotal role in tire production, ensuring uniformity and quality in rubber compounds.

Automotive Industry: From gaskets to seals, Banbury-mixed rubber finds applications in various automotive components, contributing to durability and performance.

Industrial Products: Rubber compounds processed in Banbury Mixers are integral to manufacturing conveyor belts, hoses, and other industrial products.

Advantages:

Superior Mixing Quality: The Banbury Mixer delivers unparalleled homogeneity and dispersion of rubber compounds, minimizing batch-to-batch variations.

Enhanced Productivity: Streamlined operation and automated controls optimize mixing processes, resulting in higher production throughput.

Versatility: Capable of handling a wide range of rubber formulations and additives, the mixer accommodates diverse industry requirements.

Reliability: Engineered for durability and performance, Banbury Mixers boast robust construction and precise engineering, ensuring long-term operational reliability.

Customization: Tailored configurations and options enable customers to adapt the mixer to specific application needs, enhancing flexibility and efficiency.

The Banbury Rubber Mixer remains an indispensable asset in the rubber processing industry, embodying excellence in design, performance, and sustainability. With its advanced features, versatile applications, and enduring reliability, the Banbury Mixer continues to drive innovation and efficiency in rubber compounding worldwide.

|

Item |

Specification |

| Type |

Banbury Type |

|

Mixing Capacity |

110 liters |

|

Main Motor Power |

160 KW |

|

Weight |

About 26000 KG |

|

Dimensions |

About 6620*2560*4400mm |